简体中文

简体中文

Why is There Such a Wide Price Range for Fully Automatic Glue Dispensing Machines?

When you enter the market to purchase a fully automatic glue dispensing machine, you often encounter a puzzling phenomenon: equipment with similar appearances can range in price from tens of thousands to hundreds of thousands, a staggering difference. What secrets lie behind this? Understanding the following points will help you see through the fog and make a wise investment.

**I. Core Components: The Gap Between the "Heart" and the "Brain"**

The performance and stability of a glue dispensing machine largely depend on its core components.

* **Motion Control System (The Brain):** This is the machine's command center. Low-priced models might use simple stepper motors and open-source controllers, resulting in low precision, slow response, and susceptibility to stuttering. High-end models, however, employ imported servo motors and precision motion control cards, essentially giving the machine a "powerful brain" capable of micron-level precision positioning, smooth complex path movement, ensuring every drop of glue lands exactly where it should.

* **Metering Pump & Glue Valve (The Heart):** These determine the stability and accuracy of glue output. Cheap equipment might use ordinary gear pumps, where the output volume is easily affected by glue viscosity and temperature. Higher-priced equipment is equipped with imported metering pumps, screw valves, or piezoelectric jet valves, combined with closed-loop control, allowing them to handle various glues from thin like water to thick like paste, achieving constant, uniform linear dispensing.

**II. The "Invisible Value" of Craftsmanship and Materials**

The aspects you can't see often determine the product's lifespan and reliability.

* **Mechanical Structure & Materials:** To control costs, low-priced machines may use thin profiles and ordinary connectors, which are prone to deformation and vibration under long-term high-speed operation, affecting precision. High-priced machines use high-rigidity integral frames, precision linear guides, and ball screws, ensuring the equipment remains as stable as a rock even under long-term high load.

* **Corrosion Resistance & Durability:** For corrosive glues or harsh workshop environments, high-end models often use stainless steel frames, Teflon coatings, ceramics, and other corrosion-resistant materials. These "invisible" investments directly enhance the equipment's adaptability and service life.

**III. Level of Automation and Intelligence**

The meaning of "fully automatic" varies greatly.

* **Basic Function Type:** Can only perform simple dispensing paths like points, lines, or circles, requiring frequent manual loading/unloading and parameter adjustments.

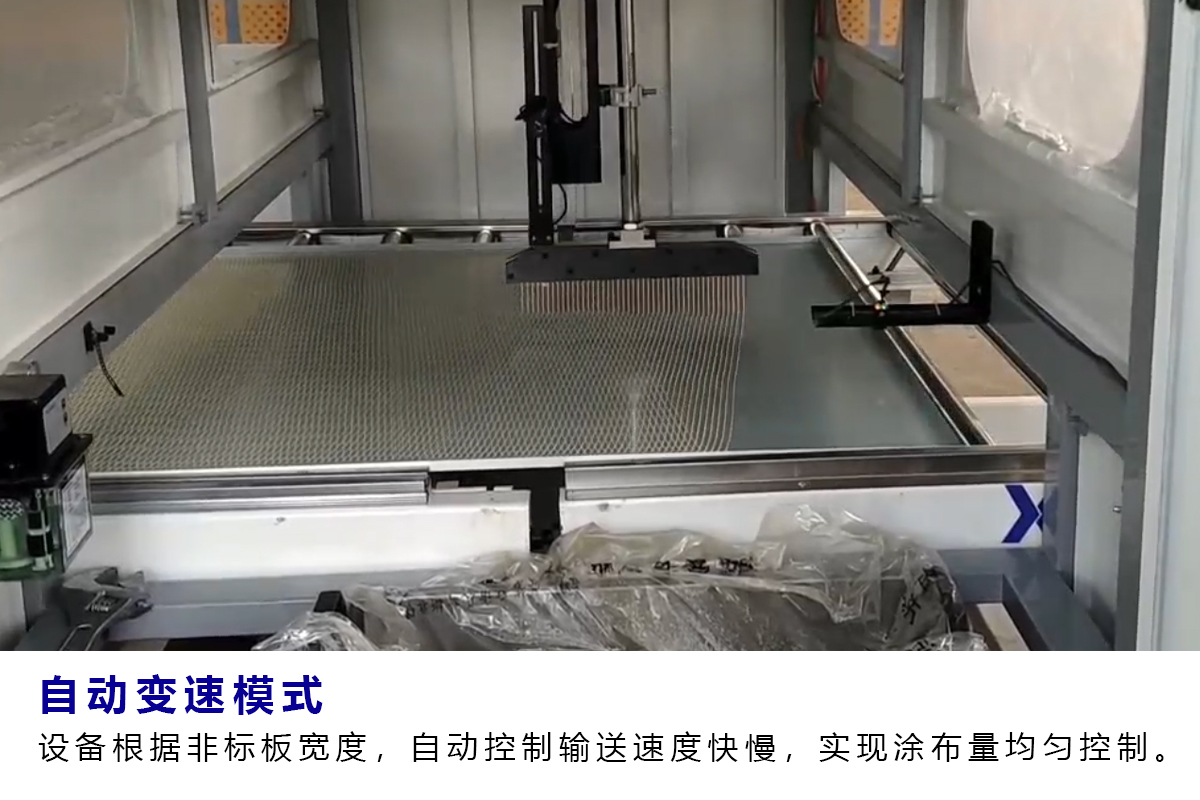

* **Intelligent Integrated Type:** Integrates vision positioning systems, automatic height sensing, glue volume monitoring, and conveyor line synchronization. It can automatically recognize product position offsets and compensate for them, achieving true "unmanned" production. These additional intelligent modules are a significant part of the price difference.

**IV. Brand, Service, and Customization**

* **Brand Premium & Experience:** A well-known brand implies mature technical积累 (accumulation), strict quality control, and a good market reputation. This value is naturally reflected in the price.

* **Technical Service & Support:** "Buying equipment is also buying service." High-end brands typically provide professional pre-sales consultation, installation, commissioning, operator training, and prompt after-sales response. These services are a guarantee for long-term stable production. Low-price suppliers often struggle to provide equivalent support.

* **Customization Capability:** Non-standard customization is another major factor affecting price. If your product process is special, requiring custom fixtures, unique paths, or integration with other equipment, the research and development costs will increase significantly.

**In Summary**

In conclusion, the price difference in fully automatic glue dispensing machines is the result of the combined effect of **core configuration, manufacturing craftsmanship, level of intelligence, and comprehensive service.**

A low price might solve the problem of "having a machine," but it may come with risks like unstable precision, frequent breakdowns, and lack of service, which can actually increase production costs in the long run.

When making a choice, it is advisable not only to focus on the initial purchase price but also to consider your own **production process requirements, capacity needs, and expectations for long-term stability.** Choosing a machine that is "just right" for you is the most cost-effective and wise decision.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist