简体中文

简体中文

Is it difficult to apply glue to large panels in refrigerated trucks? Cantilever glue spraying machine solves the problem

The arm-type glue pouring machine addresses the core challenge of "difficulty in glue application" for refrigerated truck panels, which is a key advantage over traditional manual scraping methods. It fundamentally resolves this issue through automated and precise processes.

Here is how the arm-type glue pouring machine specifically tackles the various difficulties in glue application for refrigerated truck panels:

1. **Addressing the Challenge of "Large Panel Surface, Difficult to Cover Uniformly by Manual Labor"**

Traditional Difficulty: Refrigerated truck panels can be over ten meters long and several meters wide. Manual scraping by workers makes it difficult to ensure uniform initial resin distribution across the entire panel, leading to inconsistent thickness in certain areas.

Solution by the Arm-Type Glue Pouring Machine:

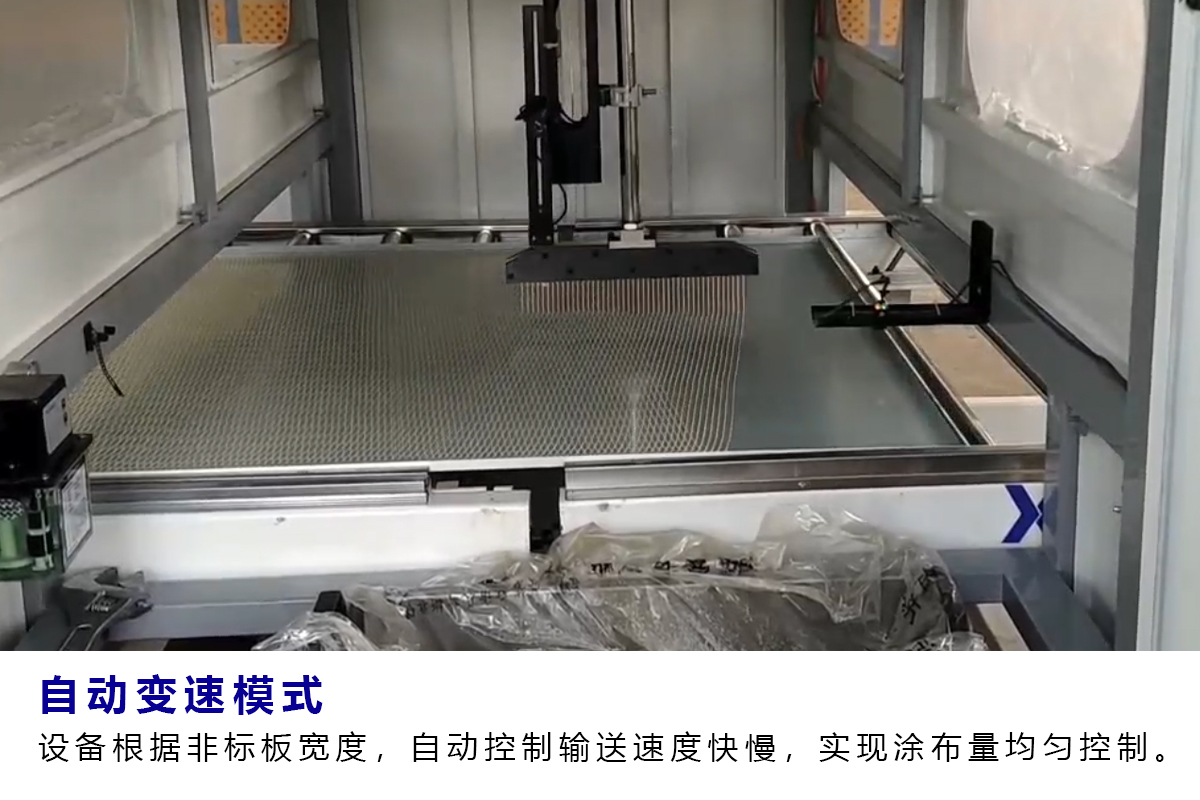

- Automated Reciprocating Scanning: The machine's arm moves back and forth precisely and evenly along the guide rail. The glue pouring head, akin to an industrial printer nozzle, uniformly dispenses the prepared resin across the entire panel surface under the control system's command.

- Precise Flow Control: Equipped with precision pumps and a control system, the machine can set the glue output per unit time, ensuring consistent resin application from one end of the panel to the other. This lays a perfect foundation for subsequent leveling.

2. **Addressing the Challenge of "High Viscosity, Poor Leveling, and Difficulty in Bubble Removal"**

Traditional Difficulty: Specialized adhesives for refrigerated trucks (typically high-strength polyurethane or epoxy resins) are highly viscous. Manual scraping is labor-intensive and prone to trapping air bubbles. The leveling time window is short, and once curing begins, defects cannot be corrected.

Solution by the Arm-Type Glue Pouring Machine:

- Constant Pressure and Volume Glue Supply: The machine provides stable output pressure to overcome the flow resistance of high-viscosity resins, ensuring smooth and uninterrupted glue dispensing.

- Heating and Vacuum Deaeration:

- Adhesive Heating: Many arm-type glue pouring machines are equipped with adhesive heating functions. Moderate heating significantly reduces resin viscosity, improving its fluidity and leveling properties.

- Central Supply System: The accompanying vacuum deaeration machine thoroughly removes bubbles generated during resin mixing before the adhesive enters the glue pouring machine, eliminating bubble defects at the source.

3. **Addressing the Challenge of "Extremely High Requirements for Surface Flatness"**

Traditional Difficulty: Refrigerated truck panels require a smooth and flat surface to ensure thermal insulation and cleanliness. Manual scraping relies entirely on the worker's skill, making it prone to wave patterns, orange peel textures, and inconsistent adhesive thickness.

Solution by the Arm-Type Glue Pouring Machine:

- Set and Maintain Adhesive Thickness: This is one of the machine's greatest advantages. By precisely controlling the glue output and the arm's movement speed, the target adhesive thickness (e.g., 1.5mm) can be directly calculated and achieved. The machine strictly maintains this thickness, ensuring product consistency.

- Reliance on Natural Leveling: Uniformly poured resin levels itself under surface tension, forming a perfect mirror-like finish. This avoids the mechanical patterns caused by manual scraping, as the machine creates optimal self-leveling conditions for the resin.

**Summary**

The arm-type glue pouring machine transforms the labor-intensive and skill-dependent task of "glue scraping" into a quantifiable, programmable, and repeatable modern production process.

It achieves this by:

- Replacing manual labor with automation to cover large surface areas.

- Ensuring uniform thickness through precise glue volume control.

- Optimizing material conditions with systematic treatments (heating, deaeration).

Thus, it fundamentally resolves the challenges of "difficulty, labor-intensity, and inconsistency" in glue application for refrigerated truck panels, significantly improving production efficiency and product yield. This exemplifies the advancement of manufacturing technology.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist