简体中文

简体中文

Glue Spreader: Disrupting Traditional Manufacturing, Why Has It Become an Industry Favorite?

In the wave of modern industry that pursues efficiency and quality, the glue spreader is becoming a core star on composite material production lines with an unstoppable momentum. From aluminum honeycomb panels to wooden boards, from aerospace to home decoration, it is everywhere. What makes this seemingly simple equipment so captivating that it has conquered the entire industry?

**1. Extreme Efficiency: A Powerful Engine for Soaring Production Capacity**

Traditional glue application methods, such as scraping or roller coating, are not only time-consuming and labor-intensive but also bottlenecks for productivity improvement. The glue spreader彻底打破了这一僵局彻底打破了这一僵局 (completely shatters this deadlock). Its precise pumping system and slit-type showerhead can instantly form a uniform, continuous curtain of glue. As boards swiftly pass through on the conveyor belt, they achieve comprehensive and efficient glue application. With speeds reaching dozens of meters per minute, efficiency increases severalfold, easily meeting the stringent demands of large-scale, assembly-line production. It becomes a powerful tool for enterprises to seize market opportunities.

**2.卓越的品质卓越的品质, The Key Guarantee for Top-Tier Products**

Quality is the lifeline of manufacturing. The revolutionary aspect of the glue spreader lies in its unparalleled coating uniformity. It eliminates common flaws like横向条纹横向条纹 (horizontal streaks), missed glue, or glue buildup often seen in roller coating, ensuring every inch of the board surface receives a highly consistent amount of adhesive. This extremely uniform glue layer is the core prerequisite for achieving perfect bonding in high molecular composite materials like honeycomb panels, directly determining the finished product's flatness, strength, durability, and ultimate aesthetic appeal. Say goodbye to quality fluctuations and deliver consistently reliable top-tier products.

**3. Cost Reduction and Efficiency Improvement: A Smart Choice for Meticulous Calculation**

Welcoming the glue spreader means embracing a "cost revolution."

* **Saves Adhesive**: Through precise control systems, the glue is almost 100% utilized on the board surface, effectively avoiding unnecessary waste, saving up to 20%-30% in adhesive consumption compared to traditional methods.

* **Saves Labor**: Fully automated operation requires only one person to supervise the entire production line, significantly reducing dependence on skilled workers and labor costs.

* **Saves Maintenance**: Reduces易损件易损件 (wear-prone parts) like rollers that directly contact the adhesive, making maintenance simpler, downtime shorter, and significantly lowering comprehensive operating costs.

**4. Flexibility and Intelligence: A Technology Platform for the Future**

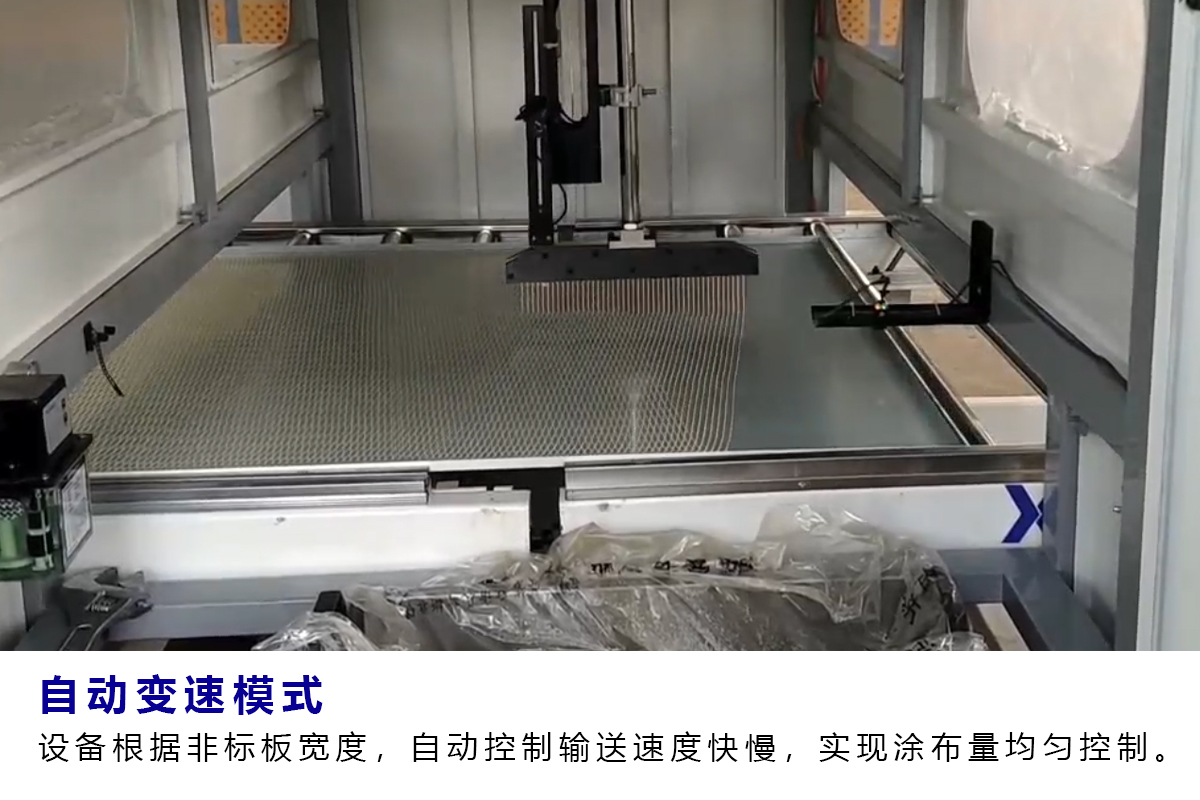

Modern glue spreaders are not just machines; they are intelligent platforms. Through PLC or computer control systems, operators can easily adjust the glue slit width, glue volume, and application mode, switching between different formulas and process requirements with the push of a button. This flexibility allows them to quickly adapt to the trend of flexible production for multiple varieties and small batches. Meanwhile, their closed glue supply system is easy to clean and supports quick adhesive changes, greatly enhancing production flexibility.

**Conclusion: Not an Option, but an Inevitability**

The popularity of the glue spreader is no accident. It is the inevitable product of industrial development's pursuit of the three core elements: **efficiency, quality, and cost**. It represents the direction of advanced productive forces, liberating operators from heavy, unstable labor, and elevating production processes to an unprecedented level of precision and reliability.

Investing in a glue spreader is not just purchasing a piece of equipment; it is investing in a path to modern manufacturing characterized by **high quality, low cost, and high competitiveness**. It has already become an important benchmark for measuring whether an enterprise possesses core manufacturing capabilities. This is the ultimate reason for its industry-wide popularity.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist